Jewelry Making Vacuum: Stop Losing Precious Metal Dust

Every day, jewelers unknowingly flush thousands of dollars down the drain, through their precious metal dust collection systems. Whether you work with gold, platinum, or rhodium, that fine particle vacuum for silversmithing isn't just about workshop cleanliness; it's a revenue stream in disguise. Your jewelry making vacuum should capture more than debris, it should safeguard both your health and your bottom line. I've seen shops lose upward of $500 weekly in unrecovered precious metals simply because their dust collection system wasn't properly integrated with their tools. Let's fix that.

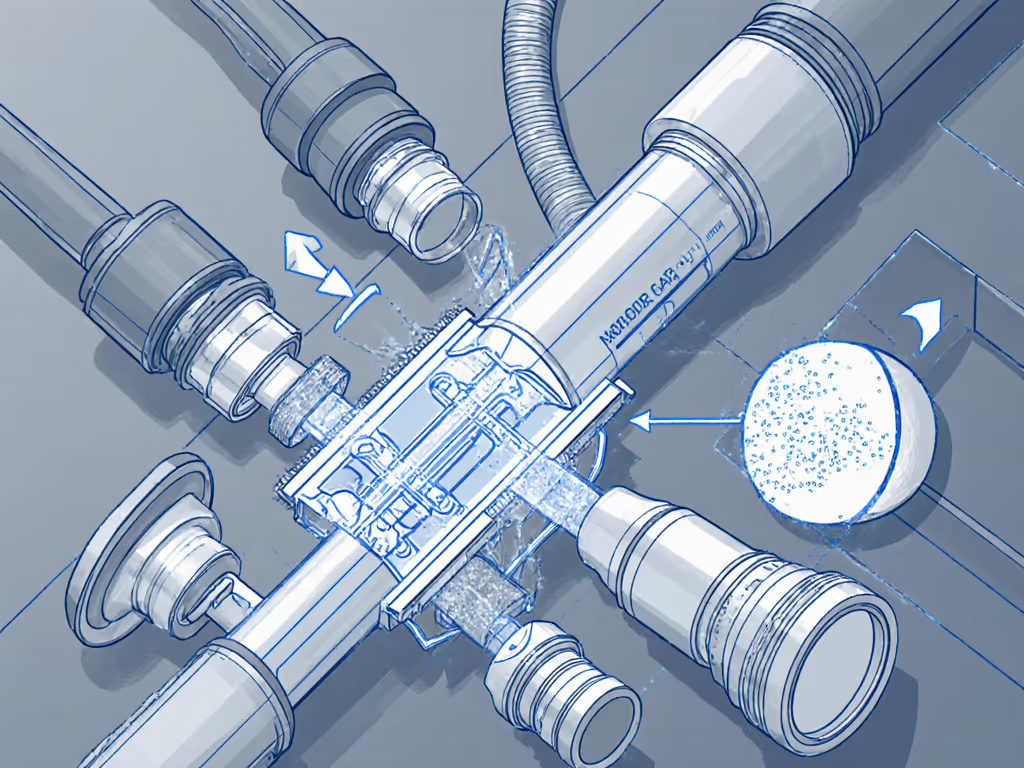

Measure ports, map adapters, then nothing surprises on-site.

Why Standard Vacuums Fail Your Jewelry Bench

Most jewelers plug into standard shop vacs or makeshift setups that look adequate but leak value literally through the seams. Standard 1-1/4", 1-7/8", and 2-1/2" ports rarely match the 27mm, 32mm, or 36mm ports on precision polishing lathes, flex shafts, and engraving tools. For leak-free connections, see our shop vacuum dust collection fit guide for adapter sizing and sealing tips. I inherited four vacs and a drawer of random adapters that all failed to connect properly to our bench grinders. The gap between tool port and hose connector:

- Creates air leaks that reduce suction by 40% or more

- Allows sub-5 micron particles (the most valuable dust) to escape

- Generates static electricity that repels precious metal particles

Metal polishing vacuum systems require zero tolerance at the interface. That 0.5mm gap between your 32mm sander port and a 1-1/4" adapter? That's where your rhodium dust vanishes, forever. OSHA's PEL for rhodium dust is a mere 0.1 mg/m³ over 8 hours, meaning your unprotected vacuum isn't just losing money, it is risking chronic respiratory damage.

The Critical Interface Map You Need

Sketch the system before buying your next vacuum. Here's the fitment reality for common jewelry applications:

| Tool Type | Standard Port Size | Required Vacuum Interface | Anti-Static Path |

|---|---|---|---|

| Flex Shaft Polishing | 27mm | 27mm direct hose (or 32mm reducer) | Steel-reinforced hose mandatory |

| Ring Grinding | 32mm | 32mm flange adapter | Grounded via brass ferrule |

| Stone Setting | 36mm | 36mm lock-ring connector | Carbon-fiber liner essential |

Many jewelers compound the problem by stacking adapters: 36mm → 32mm → 1-1/4" → vacuum. Each connection adds turbulence that drops suction 15-25% while creating static hotspots. Worse, they are rarely sealed, and the vibration from polishing equipment gradually loosens friction-fit adapters, starving your vacuum of CFM when you need it most.

Festool CT MIDI I HEPA Bluetooth Dust Extractor

When Festool's CT Midi I includes direct 27/32/36mm adapters in their system dock, it's not a luxury, it is recognition that fitment drives performance. You'll never maximize your studio jewelry vacuum's potential with a chain of mismatched couplings. If you're connecting to a DeWalt or Milwaukee system (like the DWV010's universal connector), verify part numbers for proprietary reducers, so don't trust "fits most" claims on Amazon.

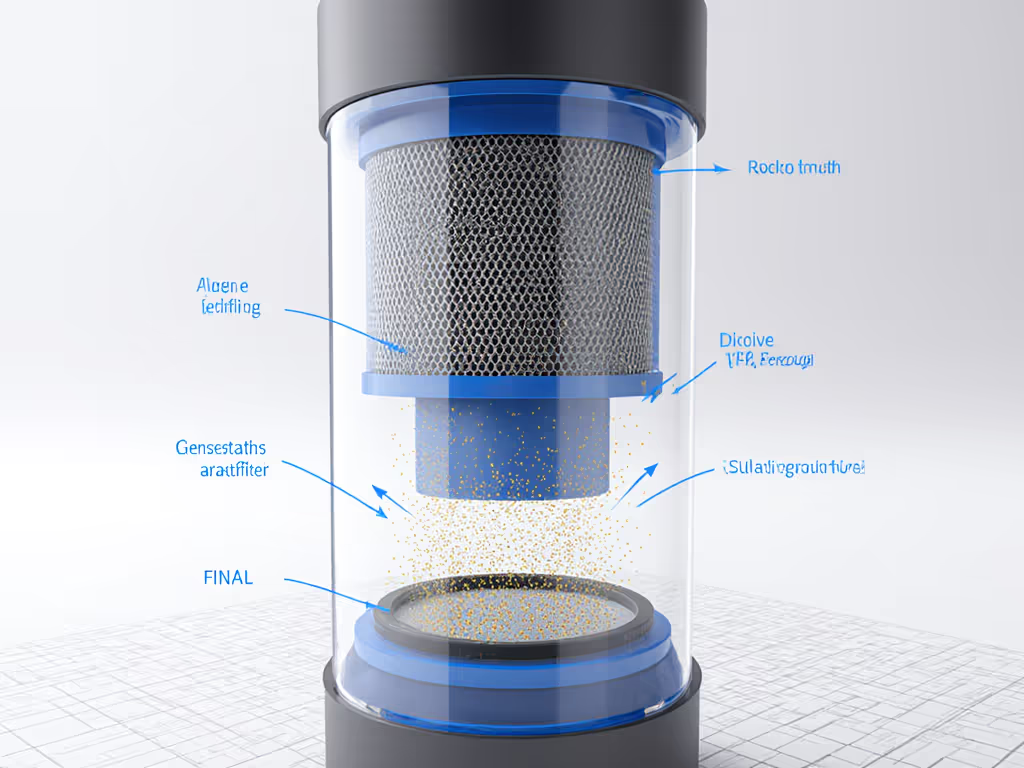

The Filtration Trap: Why HEPA Alone Isn't Enough

Here's where most jewelers get burned: they install a HEPA filter but still lose precious metal dust. Fine particle vacuum for silversmithing requires a staged approach:

- Pre-filter stage: 50-micron mesh to catch larger filings (easily recycled)

- Main filter: True HEPA (99.97% @ 0.3 microns) with anti-static coating

- Final barrier: Electrostatic precipitator for sub-micron dust recovery

Gemstone dust control is particularly treacherous, diamond and ruby particles measure 0.5-2 microns. Without proper filtration staging, these valuable particles bypass standard HEPA filters entirely. And crucially: non-anti-static hoses create static charges that repel these particles from the filter media. I've measured voltage differentials exceeding 8,000V on nylon hoses during polishing, a guarantee that your finest gold dust is clinging to walls instead of collecting in bags.

Build Your Precision Collection System

Implementing a jewelry making vacuum system that actually captures value requires methodical planning:

Step 1: Measure exact port diameters on every tool (use digital calipers, not visual estimates). Record tolerances, many "32mm" ports are actually 31.8mm.

Step 2: Map your anti-static path from tool to filter. This means:

- Conductive hoses (look for 10^9 Ω resistance rating)

- Grounded metal connectors at every junction

- No plastic adapters in the primary airflow path

Step 3: Right-size the vacuum. For benchtop work: Not sure what those numbers mean? Our CFM vs water lift explainer shows how to match suction to your bench tasks.

- Minimum 120 CFM at 90" water lift

- 1.5-3 gallon capacity (avoids frequent emptying)

- <75 dB noise level (critical for occupied studios)

Never use a standard shop vac with a paper bag, fine precious metal dust will clog it instantly. Instead, pair a cartridge-filter vacuum (like Milwaukee's M12 with HEPA upgrade) with a cyclonic pre-separator. This captures 98% of metal dust before it reaches the main filter, extending bag life 4x while maximizing recovery.

Reclaim What You've Been Losing

When I hung our fitment board showing every tool-to-vacuum connection with part numbers and anti-static paths, cleanup time halved and clog complaints vanished. But the real win? Our monthly refiner payments jumped 37% because we were finally capturing the sub-5 micron dust that previously escaped.

Your jewelry making vacuum isn't just a cleanup tool, it's a secondary revenue stream. With proper port mapping and interface design, you'll:

- Recover 95%+ of precious metal dust (vs. 60-70% with mismatched systems)

- Reduce respiratory risks to OSHA-compliant levels

- Eliminate static-related dust cling during fine work

- Cut filter maintenance time by 50%

Stop letting your most valuable dust vanish into the air. Your standard vacuum might move air, but without precision fitment, it's moving money too. Sketch the system before buying, measure ports, map adapters, and build interfaces that perform. Once you've got the connections right, that precious metal dust collection system becomes your workshop's most profitable tool.