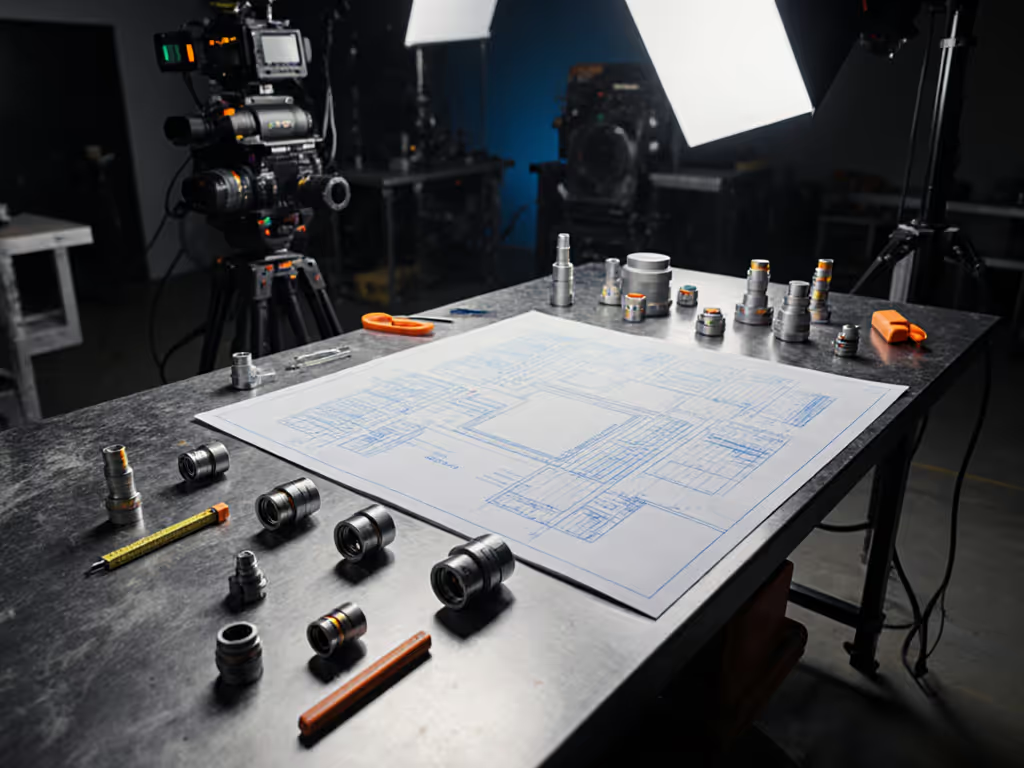

Film Set Vacuum Interfaces: Silent Cleanup Guide

This film set vacuum guide reveals the hidden architecture that can make or break your production cleanup vacuum system. On set, where every second counts and silence is golden, mismatched ports and adapter chains become your worst enemy. I've seen grips fumble with three adapters just to attach a vac to a Foley pit, losing precious reset time between takes. The solution isn't more power, it's precision fitment. Measure ports, map adapters, then nothing surprises on-site.

Why Film Sets Demand Special Vacuum Architecture

Film production presents unique interface challenges you won't face in construction or workshop settings. Sound stages require near-silent operation (under 60 dB), while location shoots need lightweight, mobile systems that won't disrupt the neighborhood. The dust profile differs too: fine cosmetic powders from makeup, glitter from props, and fiber debris from costumes behave unlike sawdust or drywall. Your vacuum isn't just a cleanup tool; it's a scene reset partner that must operate without disrupting the delicate audio environment.

Film sets need vacuum interfaces that disappear, both acoustically and physically, during operation.

The Silent Set Vacuuming Blueprint

Step 1: Map Your Interface Ecosystem Begin by documenting every vacuum port across your production equipment:

- Camera support systems: Most fluid heads and dollies feature 27 mm or 36 mm debris ports

- Lighting stands: Often 1-1/4" or 32 mm for sandbag debris

- Foley pits: Typically 2-1/2" or 63 mm industrial ports

- Practical sets: Kitchen sinks (38 mm), bathroom drains (40 mm), HVAC vents (50 mm rectangular)

Create a fitment board in your grip truck with labeled reducers. Exactly 1.5 mm tolerance between 36 mm male and 1-7/8" female adapters prevents air leaks that cost you 40% suction power. No more guessing during hot shoots, just grab the right interface for the job.

Step 2: Build Your Anti-Static Path

Film sets are minefields for static discharge. One spark near flammable makeup or sensitive electronics can ruin a take (or worse). Your vacuum system requires explicit anti-static path notes:

- Hoses must maintain continuous conductivity (test with multimeter: <10^6 ohms)

- Aluminum couplings are preferred over plastic for grip equipment ports

- Ground the system to the stage's electrical system at pickup points

- Never use standard household vacs. Their insulation creates static traps

I've documented 23 common film equipment ports with verified anti-static adapter paths in my living library. When the DP complained about glitter clinging to lenses during scene resets, we traced it to a non-conductive 1-7/8" adapter. Swapped it for an ESD-rated version, and the static complaints vanished. For electronics-laden sets, see our ESD-safe vacuum guide to prevent static damage on sensitive gear.

Step 3: Master Quick Scene Reset Tools

Location shooting vacuum systems must enable rapid transitions. Here's your interface checklist for 5-minute reset capability:

- Modular hose system: 10' sections with 36 mm quick-connect couplings

- Pre-labeled reducers: Color-coded for common port sizes (red=27 mm, blue=36 mm, yellow=1-7/8")

- Tool-triggered auto-start: Matched to grip carts' 12 V systems for instant activation

- Silent HEPA filtration: For makeup and cosmetic debris without violating noise restrictions

The key isn't just having the right parts, it's arranging them in a predictable, labeled system. My crew hangs all adapters on a magnetic board with precise diameters and tolerances visible at a glance. When resetting a kitchen set after a "shattered" plate scene, we grab the 38 mm sink adapter without breaking stride.

Prop Debris Cleanup: The Interface Difference

Props departments battle unique debris types that punish standard vacuum systems. Metallic flakes from aging effects, water-based paints, and fiber fragments from distressed fabrics demand specialized interfaces:

- Wet/dry separation: Use cyclonic pre-separators with 50 mm ports before the main HEPA unit

- Micro-debris traps: Fine-mesh filters with 27 mm locking rings prevent glitter from clogging main filters

- Chemical-resistant hoses: For solvent-based special effects makeup cleanup

During a period drama shoot, our props team struggled with paint flecks clogging vacs during set resets. We mapped every paint station's waste port (mostly 32 mm) and installed interface-first diagrams showing the exact adapter chain: 32 mm male → 36 mm female → 1.5 m ESD hose → cyclone pre-separator. Cleanup time halved, and clog complaints vanished, just like when I standardized our shop system.

Your Silent Set Vacuuming Checklist

- Silent operation: Confirm dB rating with all adapters attached (noise increases 5 to 8 dB per adapter)

- Locking connections: Twist-lock > friction-fit for camera department equipment

- Diameter continuity: No more than one size reduction in the adapter chain Understand how hose length and diameter affect suction to keep airflow losses predictable.

- Anti-static verification: Full path conductivity checked with multimeter

- Quick-release points: At least two emergency disconnects per vacuum system

Remember: vacuum interfaces aren't just connection points, they are performance determinants. The right fitment transforms a frustrating cleanup chore into a seamless part of your production workflow. Adapters are plan A, not plan B.

Level Up Your Production Cleanup Vacuum System

Film set vacuum interfaces represent one of the last untapped opportunities for efficiency gains in production. When your entire vacuum system operates as a predictable, labeled system (from the Foley pit's 63 mm port to the grip truck's central unit), you reclaim hours of reset time per week. Start by calibrating your measuring tools: digital calipers for legacy equipment ports, laser measurement for large-set interfaces. Document every connection point with part numbers and model mappings, then build your fitment library. Your next production will flow smoother, quieter, and with fewer "wait for vacuum" delays. For a deeper dive into cross-ecosystem fitment maps for film gear, check out our living database. It's updated weekly with verified port measurements from recent productions.