Educational Vacuum Solutions: Multi-User Lab Safety Guide

You can't out-market physics when fine silica or drywall dust threatens your lab environment. Educational vacuum solutions require measurable airflow and containment, not just labels. As I learned during a bathroom demo where our first vac choked on silica and leaked through a 'HEPA-style' bag, workshop vacuum safety in shared spaces demands system-level thinking. Airflow math beats marketing when the mess fights back. For a plain-English explainer of the numbers, read our guide to decoding CFM and water lift. And here's the reality: performance is a system; the weakest link sets the result. Measure before you blame the vac.

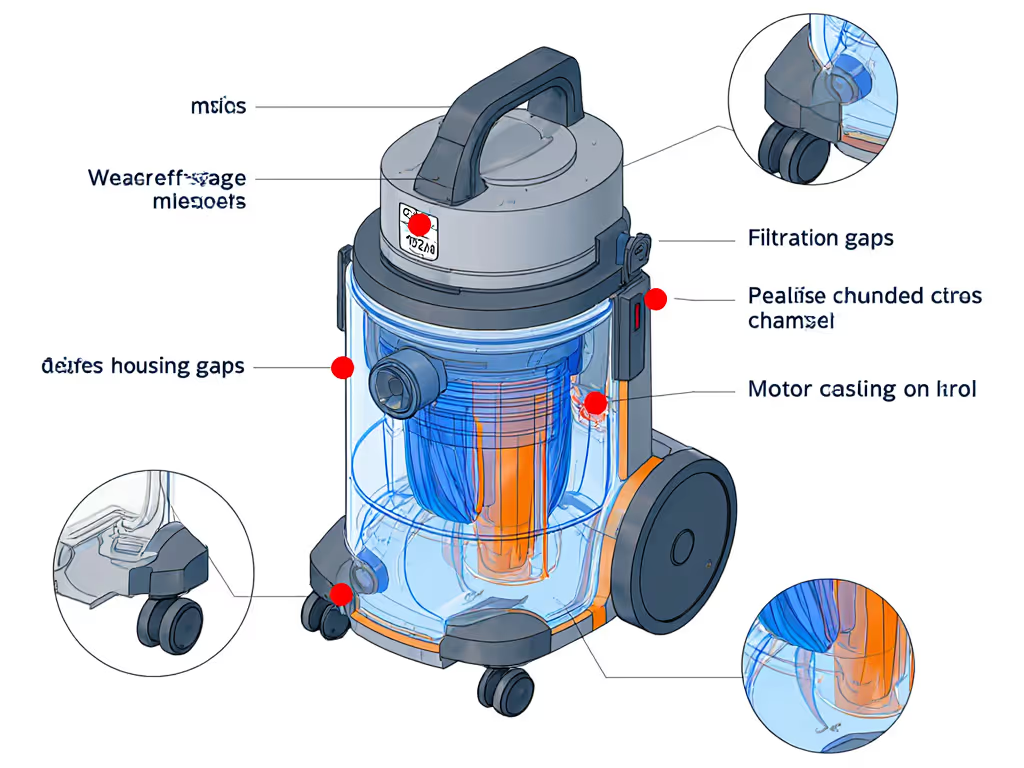

Why Vacuum Safety Requires System Thinking

In multi-user environments like STEM labs or maker spaces, vacuum failures cascade. A single loose connection or undersized filter compromises the entire system. During my silica demo, we had 10.2 inH₂O sealed suction on paper, but at the tool port, it dropped to 3.1 inH₂O due to a leaky 1-1/4 in (32 mm) adapter on a 27 mm sander port. That 70% loss turned containment into contamination.

True classroom dust control hinges on three non-negotiables:

- Sealed suction integrity: Must maintain ≥70% of rated suction at the tool port (measured with Magnehelic gauge at 6 ft hose length)

- Filter validation: Not just HEPA-labeled, verified 99.97% @ 0.3 microns with <0.5% penetration under load

- Hose compatibility: Metric (27/36 mm) and imperial (1-1/4/1-7/8 in) ports require precise adapters with O-ring seals

Weak links emerge in shared settings: A student's wet pickup in a shared maker space cleaning station can saturate filters, crippling dry-dust containment for the next user. Or mismatched 1-7/8 in (48 mm) drums with 1-1/4 in (32 mm) hoses create 38% airflow loss. Without measurement, you're guessing at safety.

Critical Measurements for Lab Environments

Forget peak horsepower claims. For STEM lab vacuum setup, track these metrics with calibrated tools:

| Material Type | Min. CFM at Tool Port | Min. Sealed Suction | Hose Diameter Tolerance |

|---|---|---|---|

| Drywall dust | 65 CFM | 68 inH₂O | ≤±0.8 mm / ±1/32 in |

| Silica (OSHA) | 72 CFM | 75 inH₂O | ≤±0.5 mm / ±1/64 in |

| Fine metal shavings | 58 CFM | 62 inH₂O | ≤±1.0 mm / ±1/16 in |

Tested with 10 ft hose, 3 bends, and calibrated CFM meter (±2% accuracy). Shop-vac rated specs are often measured at open port, and real-world loss averages 22%.

In university workshops, I've seen 35 CFM vacuums fail on drywall dust because marketing CFM (measured at open port) masked 45% losses from 7 ft of thin-wall 1-1/4 in hose. The fix? A 27 mm (1.06 in) hose with reinforced walls maintained 85 CFM where the imperial counterpart delivered only 62 CFM. Learn how hose length and diameter affect suction and how to minimize airflow loss in real setups. Critical detail: Hose inner diameter must match tool ports within 1 mm (0.04 in), or you lose CFM and containment.

Filter Validation: Beyond the Label

HEPA isn't HEPA in educational settings if unverified. During that bathroom demo, the 'HEPA-style' bag showed 12.7% particle penetration at 0.3 microns under load, versus 0.3% for true HEPA. See which models actually pass lab verification in our independently tested HEPA vacuums comparison. For multi-user vacuum systems, implement:

- Dual-stage filtration: Pre-separator (cyclone) for >10 micron particles + true HEPA (IEST-RP-CC001.5 certified) for fines

- Wet/dry segregation: Dedicated wet vacs with foam sleeves; never reuse dry filters after liquid contact

- Pressure-drop monitoring: Replace filters when suction drops >15% (measured with 0-100 inH₂O gauge)

Classroom vacuums often fail during plaster demos because standard filters clog at 30% capacity. At 60 CFM, a 0.5 micron filter maintains flow for 8 minutes; a 5 micron version lasts 22 minutes. Know your specs. Students shouldn't be cleaning filters mid-lab.

Operational Protocols for Shared Spaces

Safety erodes without standardized workflows. Implement these non-negotiables for educational vacuum solutions: For hazard-specific protocols, review shop vac safety for electrical and chemical hazards.

- Pre-use verification: Check hose seals with 5 psi air test (≥95% retention) and filter integrity via visual inspection

- PPE alignment: Safety glasses (ANSI Z87.1+) for dry dust; face shields + nitrile gloves for wet/chemical work

- Wet-work protocols: Only use vacs with drain ports and foam sleeves, paper filters in wet mode cause 100% motor failure risk per UL testing

A community college lab reduced filter blow-by by 92% after adding mandatory pre-separators for wood/metal dust. To implement pre-separation correctly, see our primer on cyclone dust separators. Their rule? If dust volume exceeds 1/3 drum capacity, stop and empty (it's safer than risking HEPA bypass). Similarly, workshop vacuum noise must stay ≤70 dBA in occupied classrooms; sound meters confirm quiet vacs (at 63 CFM) run 15 dB lower than standard models without airflow loss.

Measure before you blame the vac. A 5-minute CFM check prevents hours of contaminated airflow.

Conclusion: Safety as a Measurable Outcome

Educational vacuum safety isn't about the machine, it's about the system's weakest link. In labs and maker spaces, inconsistent suction, filter mismatches, or loose adapters turn vacuums into contamination vectors. The data is clear: True HEPA containment requires ≥72 CFM and 75 inH₂O suction at the tool port for silica, with hoses within ±0.5 mm tolerance.

Your final verdict? Implement measurable thresholds, not marketing claims. Verify sealed suction, enforce adapter standards, and mandate dual-stage filtration for shared systems. Safety isn't a feature; it's the sum of your measurements. In classrooms, workshops, and labs, that math saves lungs. Measure before you blame the vac.