Correct Shop Vac Setup for Aquarium Maintenance

If you're using a standard aquarium shop vac for fish tank maintenance without proper filtration and containment, you're risking cross-contamination and inefficient cleanup, much like that drywall crew that got cited for skipping HEPA filtration on a silica job. A proper fish tank cleaning vacuum setup requires the same level of precision as your worksite containment protocols. As a former site safety coordinator who's seen crews pay dearly for cut corners, I'll translate industrial containment principles into a foolproof aquarium vacuum system that keeps your water changes efficient, your workspace clean, and your lungs protected. Containment first; cleanup is the insurance your lungs deserve.

Why This Matters for Tradespeople Who Maintain Aquariums

Many contractors, auto detailers, and facility managers double as aquarium hobbyists. But here's the reality: your job-site discipline shouldn't stop at the tank rim. I've seen crews treat aquarium maintenance with the same "good enough" attitude that got my masonry team fined for dry cutting without HEPA filtration. Water changes seem simple until you're dealing with algae blooms from improper cleanup or cross-contaminated equipment. This isn't just about fish health; it's about operational integrity. If you're unsure about wet-only versus true wet/dry capabilities, see our Wet and Dry Vacuum Guide. When you approach aquarium maintenance with your professional containment mindset, you prevent:

- Backflow contamination between tanks

- Biohazard exposure from decomposing organic matter

- Costly equipment damage from improper wet/dry handling

- Unnecessary water waste during changes

Let's break down how to apply your job-site rigor to aquarium maintenance through this FAQ.

FAQ: Professional-Grade Aquarium Vacuum Setup

Q: Why can't I just use my standard wet/dry shop vac directly on my aquarium?

A: Because containment failures start with incompatible systems. Just like using a non-HEPA vac on silica work creates compliance risks, using an unmodified shop vac on aquariums risks:

- Filter blowout from fine particulate (similar to drywall dust clogging inadequate filters)

- Cross-contamination between tanks (like tracking mold from demolition to clean rooms)

- Water damage from improper drainage (comparable to wet pickup mistakes on job sites)

Pass/Fail Checklist:

Seal every joint on purpose (literally). If your setup has unsecured connections, it fails containment.

- Wet/dry vac has foam sleeve installed for wet pickup

- Vacuum uses a pre-filter bag for organic debris (not just the primary filter)

- Drain port directed to waste container, not the floor

- No paper filter installed during wet operation

- Hose connections locked or taped to prevent leaks

Remember: Your aquarium's ecosystem is as fragile as a newly poured concrete slab. One containment failure compromises the whole system. When disposing of used pre-filters or contaminated debris, follow our vacuum filter disposal guide.

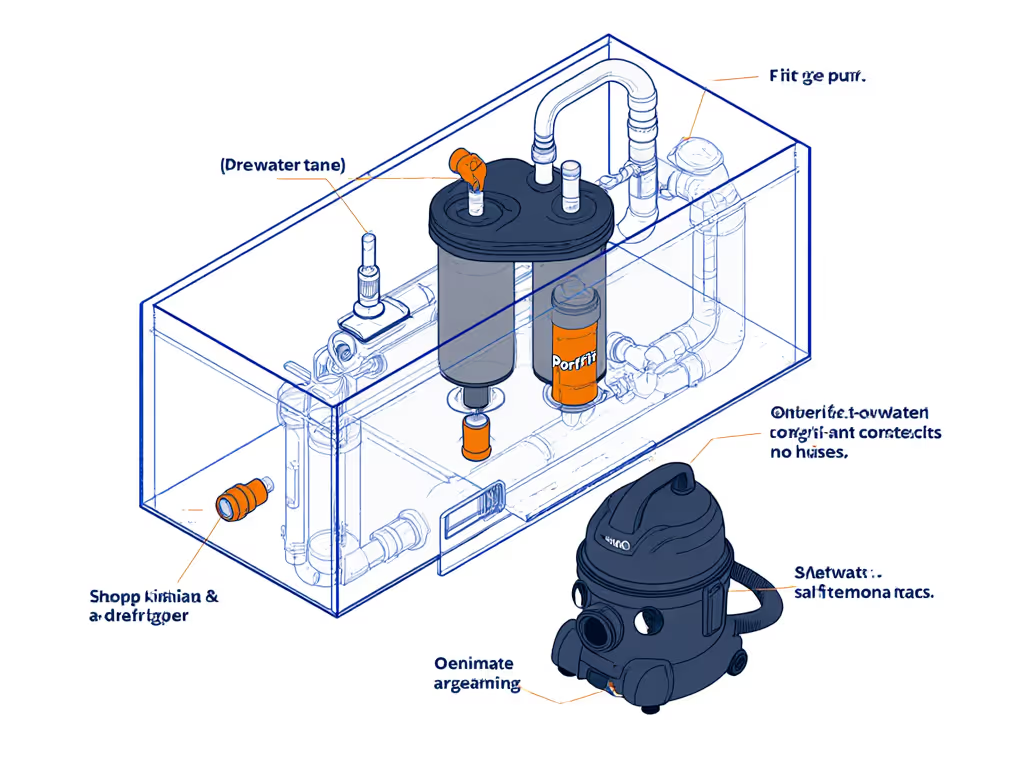

Q: What's the correct filter setup for gravel vacuuming and water changes?

A: Match your filtration to the exposure scenario, exactly as you would on different job sites. I map aquarium maintenance tasks to industrial risk categories:

| Aquarium Task | Exposure Risk | Required Filtration | Job-Site Equivalent |

|---|---|---|---|

| Gravel vacuuming technique | Fine particulate (detritus, mulm) | 2-stage: Pre-filter bag + HEPA cartridge | Drywall finishing with HEPA vac |

| Algae removal vacuum | Slimy biofilm, spores | Foam sleeve + pleated filter | Mold remediation setup |

| Saltwater tank maintenance | Salt crystals, protein foam | Dedicated saltwater kit + easy-rinse filter | Marine corrosion-resistant tools |

| General water changes | Clear water, minimal debris | Standard wet filter with foam sleeve | Post-flood cleanup |

Never use the same filter setup for different tank types. Just as you wouldn't use a drywall vac on concrete dust, don't use freshwater filters on saltwater maintenance. The salt crystals will destroy standard filters just like silica destroys non-HEPA vacs.

Python No Spill Clean and Fill

Q: How do I prevent cross-contamination between tanks?

A: Implement decon protocols like you would between job sites. I've seen crews contaminate entire aquarium collections because they didn't treat their vac like they do their demo tools. Apply these containment practices:

- Color-code your kits: Red for saltwater, blue for freshwater (like your site-specific tool labeling)

- Dedicate accessories: No sharing hoses or attachments between tank types

- Post-vac decon: Rinse entire system with vinegar solution after saltwater jobs

- Filter change protocol: Replace pre-filter bags after each tank session

This is your equivalent of the "clean zone" on hazardous job sites. Just as you wouldn't bring mold-contaminated tools into clean areas, don't let saltwater residue compromise your freshwater maintenance. Track your filter changes like OSHA logs: "last changed" labels prevent dangerous assumptions.

Q: What's the right gravel vacuuming technique for deep cleaning without disturbing substrate?

A: Precision matters as much as it does in confined space entry. Your approach must balance suction power with substrate protection:

- For fine sand: Keep vacuum 1/2" above substrate (use the "hover technique" like maintaining distance from fragile drywall)

- For gravel: Insert tube halfway, then lift slightly to let heavy substrate fall back (crimp hose technique)

- For planted tanks: Vacuum only 1/3 of tank per session to preserve root structures

Document this in your site-ready checklist: Water changes are incomplete without proper substrate cleaning. If your vacuum pulls gravel, your suction exceeds safe levels, just like exceeding silica exposure limits on a job site. Reduce hose diameter or add an airflow restrictor to dial in precise suction control.

Q: How do I adapt my shop vac for saltwater tank maintenance specifically?

A: Saltwater requires nuclear-grade containment (think of it as your equivalent of asbestos abatement). Standard wet/dry vacs fail here without these modifications:

- Corrosion-proof drainage: Use PVC piping instead of metal connectors

- Double filtration: Primary pre-filter bag + secondary antimicrobial filter

- Dedicated saltwater kit: Never reuse freshwater components

- Post-job flush: Run fresh water through entire system after each use

Treat salt residue like crystalline silica; both destroy equipment through microscopic abrasion. I've seen vac motors fail after just three saltwater sessions with improper setup. Your checklist must include: "All salt-exposed components rinsed within 15 minutes of job completion." For corrosion risks, electrical safety, and chemical compatibility, review our shop vac safety guide.

The Professional's Maintenance Routine

Your aquarium deserves the same pre-flight inspection as your worksite equipment. Implement this weekly containment check:

- Verify filter integrity: No cracks in housing, seals intact (like checking HEPA gaskets)

- Test drain connections: With water running for 60 seconds (like a pre-job containment test)

- Confirm suction levels: Able to lift 1/4" gravel without pulling it (like calibrating blower doors)

- Document maintenance: "Last filter change: [date]" label on unit

Just as I built that simple HEPA kit for my masonry crew (labeled bags, certified filters, taped joints), your aquarium vacuum system needs purpose-built components. The right setup transforms water changes from messy chores into contained, efficient operations that protect your investment and your health.

Further Exploration

Want to deepen your containment expertise for specialized environments? I recommend checking out:

- The EPA's guidelines on biological contaminant control (apply these principles to tank ecosystems)

- OSHA's respiratory protection standards (understand the filtration science behind HEPA)

- Professional aquarium maintenance certification courses (yes, this is a bonafide trade!)

Remember: Your best tool isn't the vac itself, it's the systematic approach you bring to containment. Approach every water change like a site-ready inspection, and you'll never face the cleanup failures that plague careless operators. Seal every joint on purpose, document your process, and maintain the operational excellence you're known for (whether you're on the job site or by the tank).

This guide provides operational best practices only. Always verify equipment specifications with manufacturers and comply with local regulations for water disposal and biological waste handling.