Biosafety Vacuum Setup: Medical Grade Filter Compatibility Guide

When setting up a commercial vacuum cleaner for medical environments or converting your shop medical grade vacuum for biosafety applications, filter compatibility isn't just about capture efficiency, it's fundamentally an interface problem. Too many professionals focus solely on HEPA ratings while ignoring the physical connections that determine whether your system actually delivers protected suction. As someone who's mapped over 200 tool-to-vacuum interfaces across trades, I've seen more biosafety failures from mismatched ports than inadequate filtration media. Let's dissect the compatibility matrix that separates regulatory-compliant setups from dangerous guesswork.

Understanding Medical Filtration Standards: Beyond the Marketing Hype

Efficiency Ratings That Actually Matter

Medical environments demand precision filtration, but not all "medical grade" claims are equal. Let's compare the actual performance metrics:

- Standard HEPA: 99.97% efficiency at 0.3 microns (common in basic surgical environments)

- True Medical Grade: 99.995%+ efficiency at 0.3 microns (required for certain biosafety levels)

- ULPA: 99.999% efficiency at 0.1-0.2 microns (used in critical pharmaceutical applications)

Walker Filtration's Alpha series, for example, achieves >99.9999% efficiency, critical when dealing with bioaerosols. But impressive numbers mean nothing if your filter housing creates bypass paths due to improper sealing. Pressure loss specifications (≤ 3 kPa when clean) matter just as much as capture rates; exceeding these values compromises airflow while straining your vacuum motor.

Port Size and Flow Rate Compatibility

Medical vacuum systems operate within specific flow parameters. Corning's laboratory filtration systems standardize on 45 mm neck sizes across their 150 mL to 1 L models, while industrial medical vacuum filters like the Walker A30400MV use threaded connections (1/2 inch pipe typically handling 187 Nl/min).

Flow Rate vs. Pipe Size Reference:

- 1/4" pipe: ~48 Nl/min

- 3/8" pipe: ~82 Nl/min

- 1/2" pipe: ~187-340 Nl/min

Attempting to connect a 27 mm woodworking sander to a medical-grade filtration system without proper reducers creates turbulence that degrades both filtration efficiency and airflow. For airflow tuning basics, see how hose length and diameter affect suction. Precision diameter mapping prevents these compatibility dead-ends (something I learned after inheriting four vacs and a drawer of useless adapters that couldn't connect to our sanders).

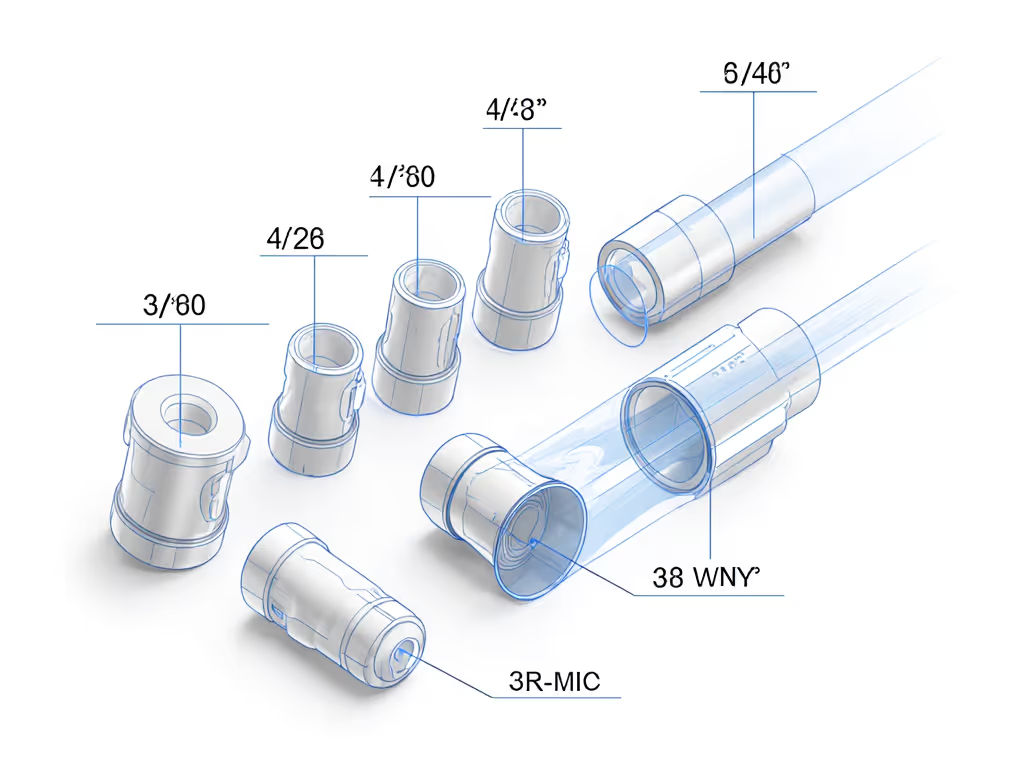

The Critical Interface: Ports, Adapters and Filter Housings

Why Fitment Determines Performance

Your vacuum's filtration rating is only valid when all components mate perfectly. A 99.999% efficient filter becomes useless if mounted in a housing with 0.5 mm tolerance gaps. I see shops install expensive HEPA filters only to leak contaminated air through poorly fitting connections between the filter housing and vacuum body.

Key interface dimensions you must verify:

- Flange dimensions (diameter and bolt pattern)

- Sealing surface tolerances (typically ±0.1 mm for medical applications)

- Thread specifications (NPT vs BSP, pitch, depth)

- Hose barb diameters (must match hose inner diameter precisely)

Beware of "universal" filter housings, medical biosafety demands explicit dimensional verification, not hopeful compatibility.

Creating a Secure Anti-Static Path

For medical equipment cleaning vacuum applications near sensitive electronics, static discharge poses serious risks. Unlike standard shop vacs, medical biosafety systems require a complete, verified anti-static path from tool port through hose to filter housing and finally to ground.

Atrix's medical vacuums address this with special conductive pathways, but third-party adapters often break this chain. Always confirm:

- Hose conductivity (≤ 10^6 ohms resistance)

- Adapter material (conductive plastic vs insulating nylon)

- Filter housing grounding points

One hospital I consulted had perfect HEPA filtration but constant ESD failures, traced to a non-conductive plastic reducer between their metal wand and vacuum. The problem vanished after we installed a properly rated conductive adapter with documented resistance values.

Building a Compliant Biosafety System: A Practical Framework

The Interface-First Design Process

Forget starting with vacuum power or filter ratings. Begin with:

- Mapping your tool ports (27 mm, 36 mm, 1-7/8", etc.)

- Documenting required flow rates based on tool CFM needs

- Verifying filter housing connection specs against your vacuum model

I've created fitment boards for 27/32/36 mm systems with labeled reducers, cutting our lab's setup time in half while eliminating filter bypass issues. Sketch the system before buying, and you'll avoid the $2,000 mistake I once made purchasing a medical vacuum that couldn't accept standard lab tubing.

Compatibility Checklist for Medical Vacuum Systems

Before committing to any biosafety vacuum systems, verify these non-negotiable interface points:

- Filter housing threads match your vacuum's inlet port (measure with calipers, don't trust marketing)

- O-ring specifications (size, material, groove dimensions) match filter element

- Hose connections maintain anti-static continuity throughout the chain

- Pre-filter stages properly interface with main filtration unit

- Drain ports (if handling biofluids) seal correctly when not in use

Solberg's HV Series medical filters exemplify proper interface engineering with their ISO 45H classification and documented 99.995% retention rate, but only when installed according to their specific dimensional requirements.

Conclusion: Engineering Certainty Into Your Setup

Biosafety vacuum performance depends first on physical compatibility, second on filtration media. The most expensive medical grade vacuum becomes compromised by a single poorly fitting adapter. For laboratory dust collection or sterile environment vacuum applications, your system is only as strong as its weakest mechanical interface.

Document your entire connection chain with precise diameters and tolerances. Also plan for proper filter disposal when capturing biohazards to stay compliant. Create a fitment reference sheet for your specific tools and vacuum models. Measure ports, map adapters, then nothing surprises on-site. This approach transforms vacuum setup from a guessing game into a predictable, compliant process.

Ready to build your certified biosafety vacuum system? Download my cross-ecosystem fitment database covering 120+ medical and industrial vacuum models with verified port dimensions and adapter mappings. Eliminate compatibility risks before your next critical job.