3D Printing Dust: HEPA Shop Vac for PLA Safety

If it isn't captured, it gets inhaled. That's not just a slogan, it's the non-negotiable reality for anyone running a 3D printer with PLA filament. While PLA is often marketed as "biodegradable" and "safer", its fine dust particles during sanding, finishing, and even printing demand serious containment. 3D printing shop vac setups with true HEPA filtration aren't optional extras; they're foundational to protecting your team's health and your business's compliance standing. Forget vague promises; let's map PLA dust collection to practical pass/fail criteria you can implement today.

Why PLA Dust Requires HEPA-Grade Capture

PLA's "eco-friendly" label creates dangerous complacency. During post-processing (sanding, cutting, grinding), it generates respirable particles smaller than 10 microns, easily penetrating lungs. A recent study using laser dust sensors confirmed PLA emissions spike with filament moisture content, reaching over 1,600 µg/m³ in humid conditions. That's 16 times higher than OSHA's permissible exposure limit for nuisance dust. And here's what trade crews often miss: PLA dust is combustible. When suspended in air near printer lasers or heat sources, it creates a deflagration risk. Containment isn't about being careful, it's about engineered controls that work under pressure. For broader hazard prevention and safe wet/dry usage, see our shop vac safety guide.

Containment first; cleanup is the insurance your lungs deserve.

FAQ: Your Critical PLA Dust Control Questions Answered

Q: Can I use a standard shop vac for PLA dust collection?

A: Absolutely not, and here's the pass/fail test. Standard shop vacs lack HEPA-certified filters (rated 99.97% at 0.3 microns). Their cartridge filters allow fine PLA dust to blow back into your workspace. I've seen masonry crews get cited when dry-cutting concrete created a visible dust cloud because their vac lacked proper filtration. Use this pre-flight checklist:

- Does your vac have a certified HEPA filter (not just "HEPA-like")?

- Are all joints taped/sealed (no gaps at filter housing or hose connections)?

- Does it include a shroud or enclosure attachment for source capture?

If any item fails, you're risking OSHA violations. Verified HEPA filtration is non-negotiable for respirable dust.

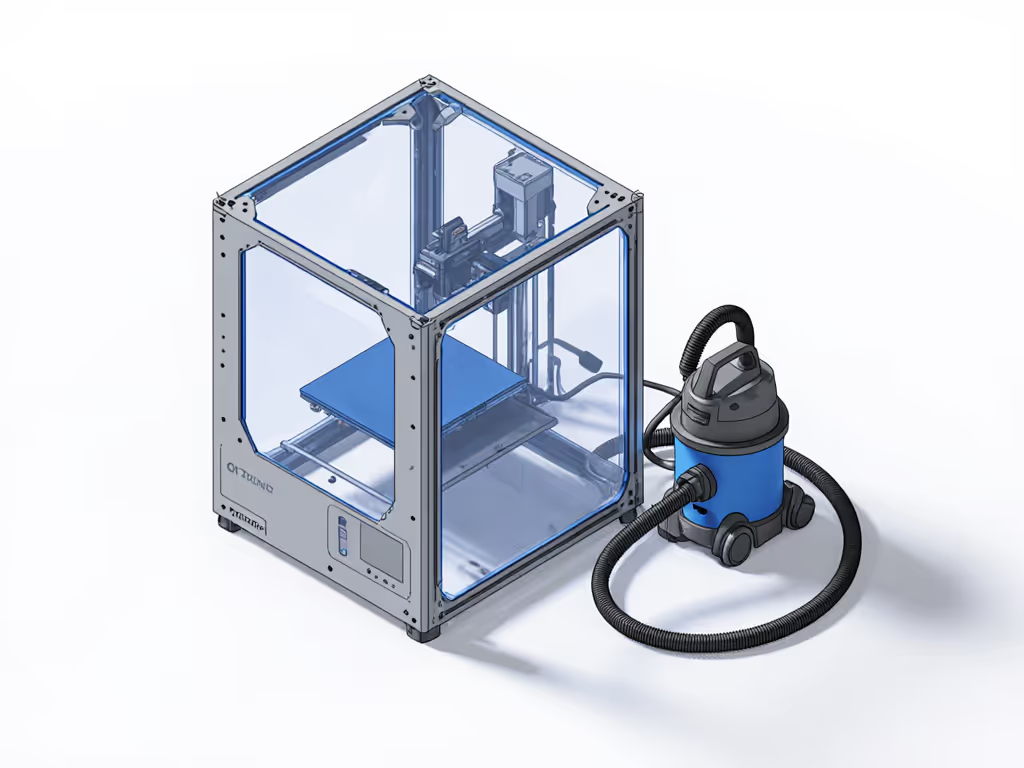

Q: How do I integrate a vac with my 3D printer enclosure?

A: Map your enclosure to airflow requirements. Many users mistakenly treat 3D printer enclosure vacuum systems as optional add-ons. They're your primary defense against airborne particles during printing. Key criteria:

- Air Changes: Your system must achieve ≥10 air changes per hour within the enclosure volume. Calculation: (Enclosure volume in ft³ ÷ 60) × 10 = Required CFM.

- Sealed Suction: Ensure no air leaks around the enclosure seams. A simple smoke test (use incense) reveals gaps.

- Filter Placement: HEPA filters must sit after the enclosure (never before the dust source).

Many trade pros I work with retrofit enclosures with custom-printed shrouds (like those in open-source libraries) that direct airflow straight into the vac hose. If you need help sizing airflow and interpreting specs, read our CFM spec guide. This turns a basic enclosure into an active capture system.

Q: What's the role of filament dust control during printing itself?

A: It's about prevention, not just cleanup. Moisture in PLA filament (common in humid workshops) increases dust emissions during extrusion, proven by particle sensor studies. Combat this with:

- Dry Storage: Seal filaments in containers with desiccant (silica gel) between uses.

- Enclosed Printers: Use printers with built-in HEPA filters on exhaust ports (common in industrial models).

- Low-Temp Printing: Keep extrusion temps ≤200°C where possible, higher heat increases particle release.

Treating filament dust control as a process, not an afterthought, reduces your vac's burden by 40% or more. To further reduce fine dust loading, add an inline cyclone dust separator ahead of the HEPA filter.

Q: How do I verify my 3D printing workshop air quality?

A: Don't guess: test with objective metrics. Borrowing tools from industrial hygiene:

- Laser Particle Counters: Monitor real-time PM2.5/PM10 levels. Target: <50 µg/m³ during active printing/sanding.

- Tape Tests: Press clear tape on surfaces after printing. Visible dust = source capture failure.

I require crews to run these checks weekly. Document results; it's your proof of due diligence if inspectors visit. Good air quality isn't just compliance; it's how you keep detailers from coughing through client jobs or facility managers from calling OSHA.

Q: Are fume extractors enough for PLA?

A: Fume extraction vacuums only handle vapors, not particulate dust. PLA's primary hazard is solid particles, not VOCs (unlike ABS). Critical distinction:

- Fume Extractors: Target gases (e.g., carbon filters for ABS fumes).

- HEPA Dust Vacuums: Target particulates. Required for any sanding, cutting, or high-emission printing.

Using only a fume extractor for PLA post-processing is like using a sieve to hold water, it passes the test but fails the job.

Your Action Plan: Building a Site-Ready PLA Dust Kit

Forget complicated systems. I've built foolproof kits for contractors that pass surprise inspections. Replicate this for your workshop:

- The HEPA Vac Core: A dedicated vac with certified HEPA filtration (e.g., a HEPA-equipped corded model or a battery vac with a washable HEPA cartridge).

FLEX 24V 1.6 Gallon Wet/Dry Vacuum

- Sealed Capture Points: Custom-printed shrouds/adapters (Thingiverse has free STL files) that fit your printer's ports snugly, no gaps.

- Pre-Flight Labels: Tag your vac with: "HEPA CERTIFIED: FOR DUST ONLY" + filter change date. For maintenance intervals and cleaning technique, follow our shop vac filter cleaning guide.

- Weekly Verification Log: Record particle counter readings and visual tape tests.

This isn't overkill, it's how you avoid the $15,000 fine I saw a crew pay for dry-cutting concrete with a non-HEPA vac. Health, compliance, and client trust start with documented containment.

Final Pass/Fail Reality Check

Your 3D printing workshop air quality strategy lives or dies by three things:

- Source Capture: Is dust grabbed at the tool before it disperses?

- HEPA Verification: Does your vac have certified documentation (not marketing claims)?

- Routine Testing: Are you validating performance weekly?

If you can't prove "yes" to all three, you're gambling with lungs and liability. PLA dust is invisible until it's too late. Build your containment system today, not after the first OSHA notice.